Alimentación con mayor precisión

y mejor distribución para la etapa

de precría del camarón

"The perfect combination of technology and efficiency to maximize growth and profitability in your estanques de precría

Automatic Feeding

Edición Precría

Optimize the first stage of cultivation with precise and efficient feeding. This system ensures uniform feed distribution, reduces waste, and promotes accelerated growth in fewer days. Its advanced technology improves feed conversion rates and maximizes profitability.

Smart technology for faster growth

- Precise and uniform distribution of alimento de precría.

-

Distribution range of 0.3 a 1.2 mm.

- Better shrimp development from the start reducing waste and maximizing profitability.

- Improved management efficiency and control for estanques de precría.

- Between 400,000 and 500,000 animals per unit.

EVERY ECOSYSTEM IS UNIQUE

EVERY ECOSYSTEM IS UNIQUE

1 Solution for

1 Ecosystem at a time

1 Solution for

1 Ecosystem at a time

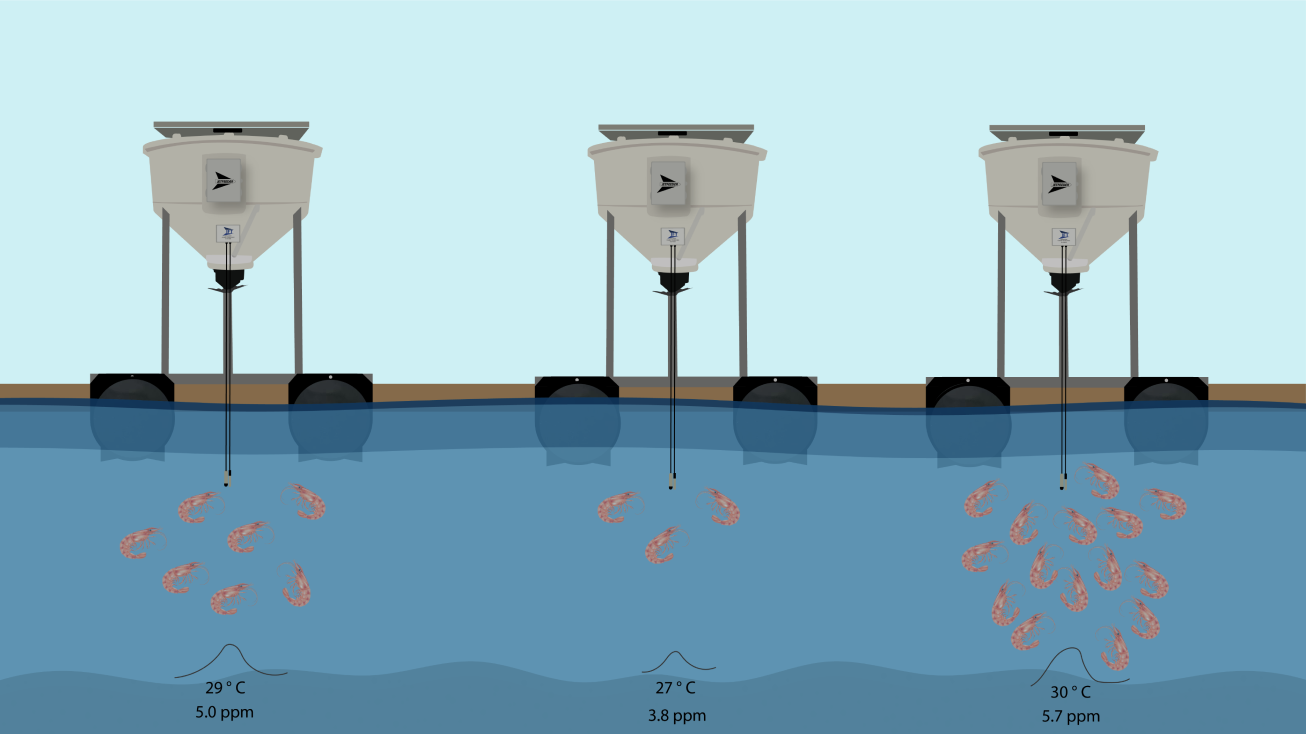

INTELLIGENT FEEDING TECHNOLOGIES

Our advanced feeding system leverages a hydrophone and integrated sensors to monitor shrimp behavior. It continuously tracks water temperature and oxygen levels, enabling precise, responsive feeding that maximizes growth and resource efficiency.

INTELLIGENT FEEDING TECHNOLOGIES

Our advanced feeding system leverages a hydrophone and integrated sensors to monitor shrimp behavior. It continuously tracks water temperature and oxygen levels, enabling precise, responsive feeding that maximizes growth and resource efficiency.

Intelligent Feeding Technologies operation

Faster growth

Bigger shrimps

More profits

- Adaptable for each ecosystem.

- Operates from 3 grams.

-

No delays or learning curves, just

efficient automation. - Easily integrates with both new and existing feeders.

GET TO KNOW OUR SOFTWARE

JETFEEDER

Allows customization of various aspects: From adjusting pool settings to establishing feeding mode, managing feeders, selecting the type of food, and more.

Initial configuration to adjust key aspects such as: initial density, weight, and start date.

Alerts for ponds and automatic feeders, with immediate notifications of events, as well as the shrimp farm status, for precise and up-to-date control.

The weekly production data includes essential information such as pond density, average weight, and registration date. It performs automatic calculations of biomass and mortality, providing a detailed and efficient insight into performance.

Enables effective and customized management of feed supply.

Records key information, including density, average weight, and fishing date. These data provide a comprehensive view of productive performance.

Allows detailed and systematic examination of the information generated during the production process..

Provides a detailed summary of the feeding, along with the report of relevant alerts, including hydrophone data, temperature, battery status, solar panel performance, and communication. Predictive reports of components based on historical data..

Why choose our Automatic Feeders?

- Offline Operation

- Remote Control Capabilities

- Build to Endure

- 99% Dosing Accuracy

- Simple Installation & Maintenance

- Centralized Managemet.

- Clumping Elimination System.

- User-Friendly Feeding Scheduler

- Operates offline.

-

Can be managed

remotely.

-

Withstands rigorous and

flexible feeding

programs.

-

Dosing accuracy

of 99%

- Easy installation and maintenance.

-

Centralised management

from a PC

-

Feeding schedule easy to use

easy to

use.

-

Disposal system

of lumps.

Customize your ecosystem

Capacity

Launch radius

Structure

Intelligent feeding technologies